Climate-friendly wooden buildings rise across U.S. and Europe

The year 2025 is “pivotal” for mass timber construction, which is growing at around 20 percent a year. Read More

- The number of mass timber building projects has grown about 20 percent annually, and today there are over 2,500 mass timber projects built or in progress in the U.S.

- The new Under Armour building in Baltimore saved over 69 percent on embodied carbon by replacing steel and concrete with mass timber.

- Mass timber is generally more expensive up front, but cost savings in construction and over the building’s life cycle can level that playing field.

While sustainable solutions are facing drastic funding cuts and even outright opposition, mass timber as a sustainable construction material is steadily gaining traction across the United States.

Construction using mass timber began in 2015 in the U.S., and since then the number of projects has grown about 20 percent annually. Today, over 2,500 mass timber projects are built or in progress in the U.S., including corporate offices for companies such as Google, Microsoft and Under Armour.

This is a “pivotal year” for mass timber construction, wrote Ricardo Brites, director of engineering and virtual design and construction at Mercer Mass Timber, on Woodworking Network.

Made of structurally engineered timber beams, these buildings are not only climate-friendly, but also beneficial for employees: They offer substantially lower embodied carbon along with noticeable positive impacts on occupants.

“We have lots of tech firms and big companies that say, ‘Hey, we’re battling it out for workers. We want the best space possible,’” said Bill Parsons, chief operating officer at WoodWorks, a non-profit industry organization for timber construction. “A good office has been really important to people, and those tend to be wood offices.”

How mass timber stacks up

Buildings and construction account for 37 percent of global greenhouse gas emissions, according to a 2023 report by the United Nations Environment Program. The production of cement and steel for construction accounts for 11 percent of global emissions.

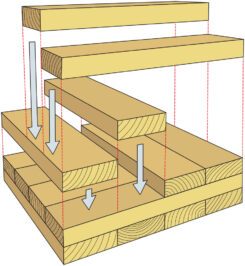

Mass timber is made of layers of lumber glued together to form a single, strong beam. The two most common varieties are cross-laminated timber, where lumber boards alternate directions as they are stacked, like a Jenga tower, and glue-laminated timber where boards are stacked in parallel.

Replacing conventional building materials with mass timber has the potential to reduce global emissions by 14 percent to 31 percent, according to the U.N. report — including from carbon stored in the wood, displacing fossil fuels and less carbon-intensive production and construction methods.

The new Under Armour building in Baltimore saved over 69 percent on embodied carbon by replacing steel and concrete with mass timber, according to Gensler, the architecture firm that designed the building.

“The use of mass timber was a lead contributor in reducing the site’s carbon emissions and supported a quicker, more seamless construction process,” said Kathy Blessington, vice president of real estate at Under Armour, in an email.

While some builders and regulators are wary of supposed fire risk with mass timber buildings, regulations in the U.S., France and elsewhere have gradually shifted to accept multistory wooden buildings, which, in fact, perform comparably to steel and concrete buildings in regard to fire resistance.

Mass timber’s inherent fire-resistant properties have been well-established, said Edward Becker, associate professor of architecture at Virginia Tech. “The evidence of the success of these fire tests and the safety for the general public is evidenced in the international building code changes over the last couple of years.”

It is paramount, though, that mass timber is sourced responsibly. The Forest Stewardship Council (FSC) and Sustainable Forestry Initiative (SFI) provide certification for products that come from responsibly managed forests with safeguards that prevent deforestation.

Designers, architects and construction managers “should check with the supplier,” said Becker. “It’s critical to look for things like FSC sourcing and SFI sourcing. That’s an easy way to make sure that it’s ethically sourced.”

Mass timber’s popularity boom

Legislation that promotes and programs that fund mass timber, such as the Mass Timber Federal Buildings Act and the Wood Innovations Grant Program from the USDA, are still progressing, for now. But wider repercussions from government funding cuts are affecting the industry.

“While we haven’t seen specific cuts to mass timber programs themselves, the broader forestry infrastructure that supports our industry is facing significant reductions,” said Nick Milestone, chief operations officer at Mercer Mass Timber.

Data from the 2024 International Mass Timber Report shows steady increases in production in Canada and the U.S., from 158,000 cubic meters in 2019 to 393,000 in 2023, and a climb in mass timber buildings constructed annually from 151 to 279 in that same period.

While mass timber offers important sustainability attributes, they’re only a secondary reason why builders are increasingly adopting it.

“I think sustainability has been further down as more of a benefit overall,” said Parsons. “The driver in my mind is that people figured out how they can make a very cost-effective, beautiful building.”

Cost comparisons for mass timber versus concrete or steel vary on a case-by-case basis. Mass timber is generally more expensive up front, according to research from Virginia Tech, but cost savings in construction and over the building’s life cycle can level that playing field. Mass timber can also be disassembled and reused at the end of a building’s life.

“When we do a mass timber building, contractors will estimate the cost and you might see a 20-30 percent premium on top of traditional building material,” said JJ Rivers, principal and studio director at Gensler. “But mass timber is incredibly light compared to concrete, so there’s savings on foundations. And when you look at the speed of erection you have lower labor costs and shorter schedule durations.”

The quicker speed of construction, due to mass timber’s lighter weight and pre-fabrication, means getting occupants into buildings quicker and generating rents sooner. Lease rates also tend to be higher in mass timber buildings.

As mass timber demand in North America grows, domestic suppliers are doing their best to keep up. Over the past decade, 13 new production plants have opened in the U.S. But builders still rely on imports from Europe, where the industry has enjoyed a few extra decades of maturation.

The U.S. has substantial forest resources, and even under aggressive logging scenarios, national forest cover is expected to grow 18 percent by 2035, according to research by the University of Washington.

Corporations adopting mass timber

Sustainability attributes and costs tell one part of the story, but the x-factor with mass timber buildings is how their occupants feel.

Studies have shown that living or working in a mass timber building, particularly when the wood is exposed, improves occupants’ mental health and well-being, even lowering their blood pressure and heart rates.

“It takes a little bit of explaining at first, but when people walk inside a mass timber building for the first time, especially when the wood is exposed, you really don’t need to explain anything else,” said Becker. “The building feels better, smells better and looks better.”

It’s a big reason why corporations are turning their attention to mass timber.

“We recently interviewed some companies in Norway about their use of mass timber buildings, and they all said they would do it again because of how it makes their employees feel,” said Becker. “They’re better able to retain and attract higher-quality employees because of the excellence of their work environments.”

Most mass timber buildings still employ some concrete and steel, but growth is trending in the right direction.

“Hybrid buildings are the next big thing,” said Milestone. “I believe that the symbiotic nature of steel and mass timber represents the future of construction in North America.”