How Colorado became a circular economy model

Dedicated landfill fees are making the state a "leader in developing circular economy solutions." Read More

- The state is trying to create a homegrown remanufacturing sector that keeps material in the state and out of landfills, creating new jobs in the process.

- A network of public/private entitites and initiatives is helping build the circular economy.

- For now, a fully sustainable ecosystem that collects material from across the state and includes a viable reuse and remanufacturing sector remains a distant vision.

A decade and a half ago, Colorado — a fossil fuel-producing state governed by Republican Bill Owens — would have seemed an unlikely candidate to forge a thriving circular economy. But a combination of progressive political leadership, a core of innovative technology developers with access to funding, regional alliances and consumer enthusiasm has shaped an emerging ecosystem of startups, public entities and nonprofits that offer a circular economy roadmap for other states.

At the center of this movement is Laurie Johnson, founder and CEO of Circular Colorado. The former COO of a hauling company and former executive director of Recycle Colorado, Johnson founded Circular Colorado in 2021 with the mission of “establishing Colorado as a leader in developing circular economy solutions.”

“We’re building a model that can be replicated across states and across regions,” Johnson said during an April 29 workshop at Circularity 25 in Denver. “We’d love to see this happen across the country.”

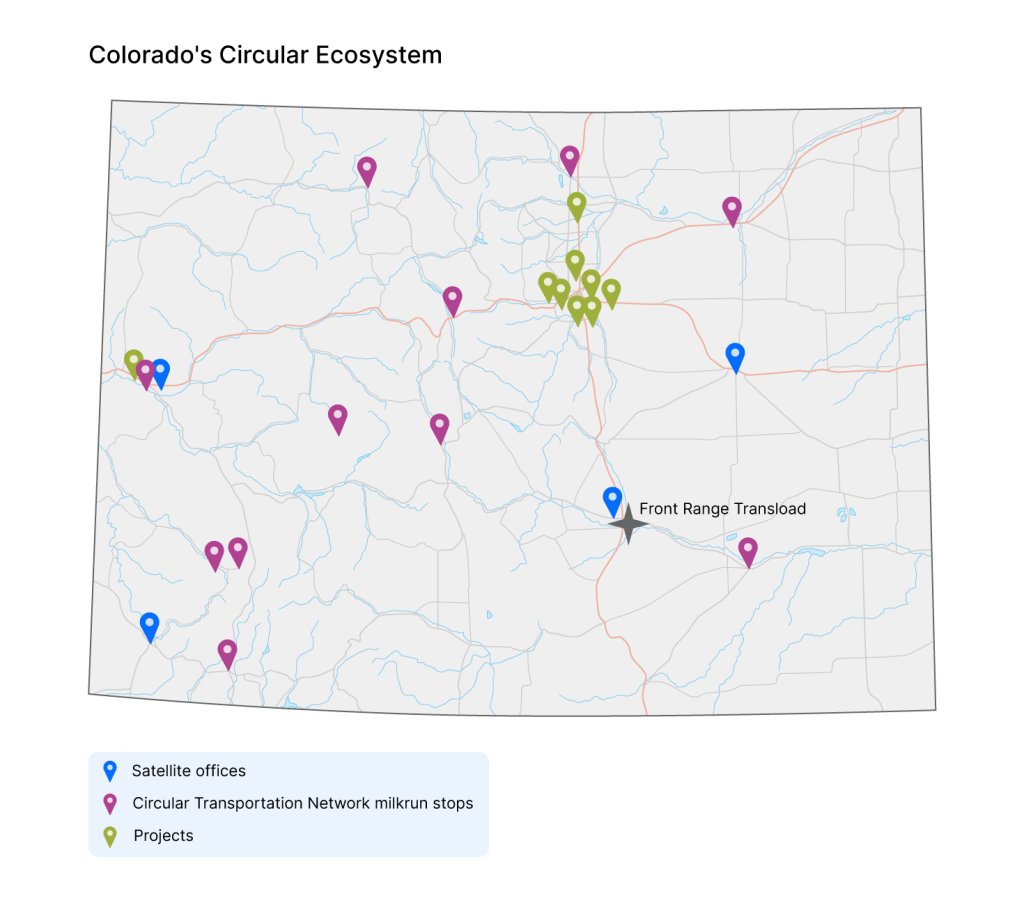

Source: Sophia Davirro/Circular Colorado

Remote communities in mountainous terrain

Colorado’s circular journey began in 2019 with the passage of a waste diversion law for the Front Range, which includes the Denver metropolitan area. At that time the state’s recycling rate for waste materials was stalled at around 16 percent — well below the national average of 32 percent.

The state’s mountainous terrain, isolated rural communities and low population density outside of a few large cities make recycling challenging

The diversion program, which originally assessed landfill tipping fees for haulers and dumpers that totaled $15 million annually, has been succeeded by a statewide program that generates $20 million a year for recycling and other circular initiatives.

The money is funneled into grants awarded and administered by the Colorado Circular Communities (C3) Enterprise, a public-private entity established in 2024 under the aegis of the state’s Department of Public Health and Environment.

Funding from a dedicated source of revenue means that the C3 program does not have to go through the state legislature to support its grants, said Deputy Director Jeff Stalter of Colorado Circular Communities on the April 29 panel: “We now cover the whole state, and we have money we can spend — it’s not appropriated by the legislature so we don’t have to put out [requests for applications].”

C3 contracted with Circular Colorado to build two additional initiatives:

The Circular Economy Development Center aims to reduce greenhouse gas emissions and protect air and water quality by establishing a fully closed recycling, reuse and remanufacturing system in the state.

The center would “move beyond the recycling industry to embrace the industries of manufacturing, transportation and other sectors that all play a role in circular economy creation,” Johnson said at the time.

The Circular Transportation Network is designed to conquer the state’s sheer geographic expanse, mainly by repurposing delivery trucks that previously deadheaded, without loads, back to their point of dispatch. The returning trucks will serve central aggregation points, including one opened in Pueblo in southern Colorado, on April 22.

The mountain communities and rural towns often have no way to transport recycled materials, said Johnson at Circularity 25. “These trucks would go out and come back empty. Now they deliver recycling that gets aggregated in Pueblo, baled and on to market.”

The market would comprise a homegrown remanufacturing sector that keeps the material in the state and out of landfills, creating new jobs in the process.

“If you want to build manufacturing in your state, what better way to start than with feedstock that’s already available in your state?” said Alice Havill, a founding partner at Fractal Climate and a board member of Circular Colorado.

Tires into barriers

Together, those four programs — Circular Colorado, the Colorado Circular Communities Enterprise, the Circular Transportation Network and the Circular Economy Development Center — form a supportive architecture that is already achieving tangible results.

Pretred, an Aurora, Colorado, company that turns discarded tires into “crumb rubber” for use in highway barriers, received an $11.2 million grant from the Circular Communities Enterprise in February to expand its operations. Colorado typically burns or buries millions of old tires each year.

“Pretred would not be here without support and assist of these individuals and organizations,“ said founder and CEO Eric Davis.

Pretred’s goal is to produce 30,000 barriers a year, using 4 million waste tires from across the state.

Another beneficiary is TERSUS Solutions, which uses a carbon dioxide-based cleaning process to recover and process materials from apparel, sleeping bags, personal protective gear and the like for brands including Patagonia, The North Face and New Balance.

Last year, said TERSUS CEO Peter Whitcomb, the company saved 5 million gallons of water and kept 1.5 million garments out of landfills.

“What’s the frontier? Killing dry cleaning and water-based cleaning,” Whitcomb said.

Encompass the region

All of this is encouraging, but single-state recycling can only go so far in building a truly circular economy: waste knows no state borders, and millions of tons of products that originate in Colorado get discarded in neighboring states, many if not most are much further behind in their circular journey.

Johnson’s ultimate goal is a truly regional ecosystem that includes all types of materials and all forms of recycling. That requires a “sustainable systemic collection system that people actually use,” plus a core of viable reuse and remanufacturing companies to consume and repurpose the full stream of recycled materials. For now, that remains a distant vision.

During the Circularity 25 workshop, Johnson laid out the structure and roadmap that other states and other organizations can use to begin building the sort of circular ecosystem that is well on the way to operation in Colorado:

- Explore the challenge

- Identify the gaps

- Develop the strategy

- Organize the players

- Execute the solution

- Manage the process to completion

“We assemble the solution,” she said of Circular Colorado. “Site selection, permitting, funding — we’re like the quarterback, the nucleus, the ones who go along and keep everything proprietary and everything moving.”

The tight weave of political support, public-private partnerships and a dynamic leader such as Johnson is unlikely to be exactly replicated elsewhere. But the template has been established.

[Join a vibrant community of leaders and innovators driving cutting-edge tools, business strategies, and partnerships to protect and regenerate nature at Bloom, Oct. 28-30, San Jose.]

Subscribe to Trellis Briefing

Featured Reports

The Premier Event for Sustainable Business Leaders