How extended producer responsibility fees can fuel innovation

Companies can turn compliance costs into innovation capital. Read More

- Extended producer responsibility programs in seven states are set to reward sustainable packaging choices and penalize less circular material choices with higher fees.

- Companies that shift away from high-fee materials unlock hundreds of thousands in savings.

- Those fee savings can fuel further investments in R&D, material innovations and packaging recovery.

The opinions expressed here by Trellis expert contributors are their own, not those of Trellis.

You’ve probably heard of the rebound effect — the phenomenon where savings from increased efficiency (such as lower energy bills) are then spent on other goods that ultimately reduce the expected environmental benefit of the original efficiency efforts.

In your own life, though, you’ve probably seen that it doesn’t have to work this way. Maybe you’ve set aside the money saved from lowering your energy bills by upgrading to smart thermostats or other sustainable home projects, such as installing more efficient appliances. These savings can function as capital for other improvements, and, in turn, snowball into more savings.

Sustainable packaging is approaching a similar opportunity for savings. Right now, seven states are about to mandate packaging fees through extended producer responsibility (EPR) programs. Under EPR programs, materials — and their fees — aren’t created equal. These programs use a technique called eco-modulation to essentially grade materials on a curve: the lower the environmental impact, the lower the fee for producers. In practice, this means flexible plastic, for example, often has higher fees than more easily recycled materials.

As these programs launch in these states and potentially advance to others, companies can unlock a new opportunity to save on fees, and then reinvest the savings back into more sustainable packaging options. Call it “improvement capital” for lower-carbon materials, more collection programs and smarter sortation technology.

Potential savings for lower-impact materials

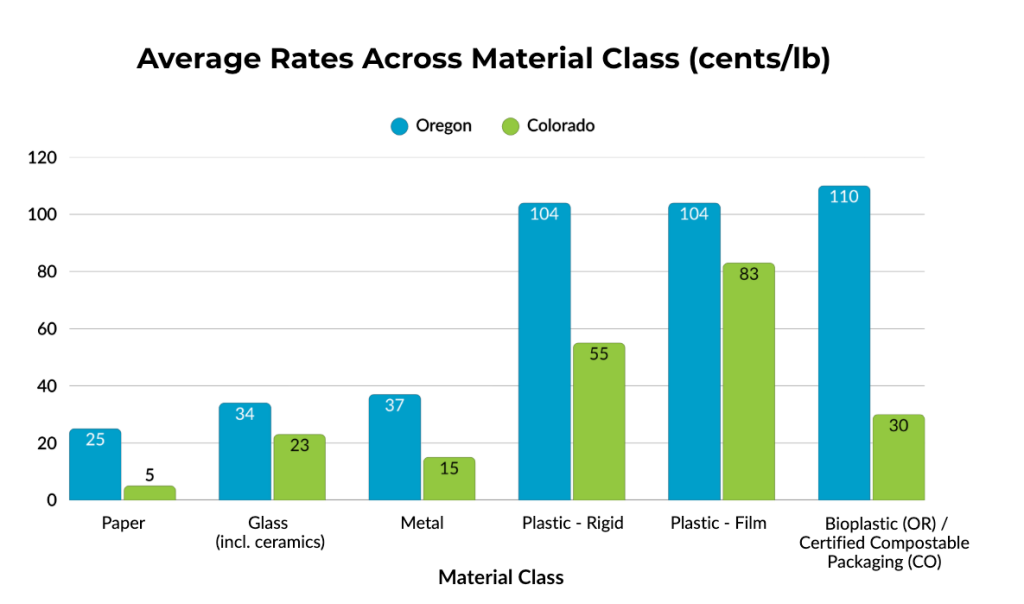

We find the first steps of improvement capital in Oregon and Colorado, the first to publish the fees that packaging producers will be charged for a wide range of packaging materials such as glass, aluminum, rigid plastic, flexible plastic and compostable packaging.

To look at broad trends, it helps to combine the wide range of materials covered under these laws into a few select categories and to average the fees per category. For example, the fees for rigid plastic vary from 17 cents/lb for PET plastic (used in packaging such as water bottles) in Oregon to 171 cents/lb for “rigid other” in Colorado.

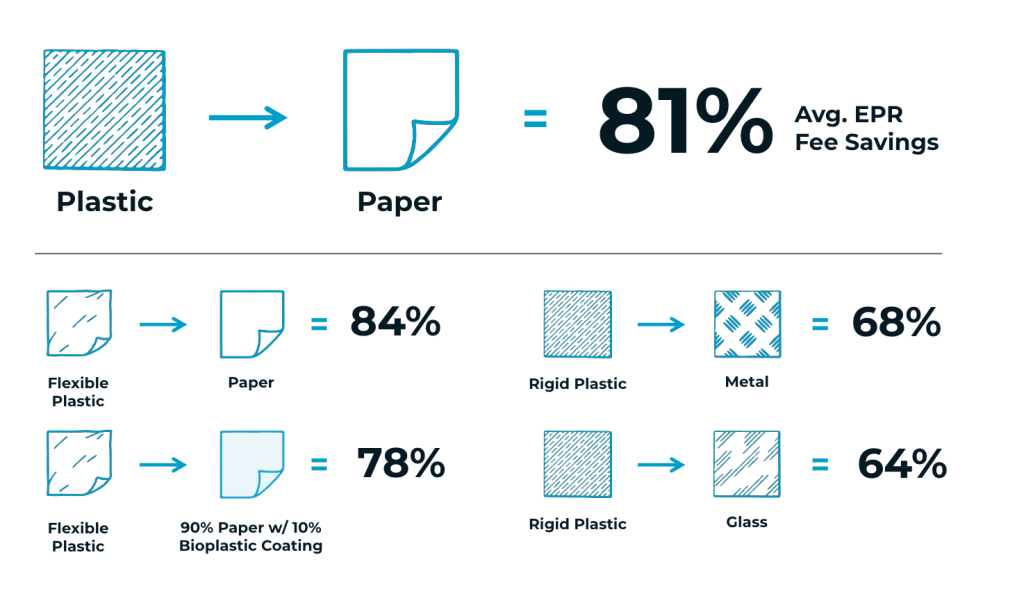

Looking at the average fees in Oregon and Colorado, we see that moving from rigid plastic to paper is a roughly 81 percent fee savings. Moving from rigid plastic to metal or glass gives companies savings in the 60 percent range, and moving from flexible plastic into a paper package with a bioplastic coating yields approximately 78 percent in savings. The takeaway? Companies could see substantial savings from switching to different materials — and these switches are reinforced by consumer perceptions about which materials are more sustainable.

What might these savings look like for a typical company? To answer that question, imagine this:

- A consumer packaged goods brand is planning a switch from 34,000 tons of flexible plastic packaging to a paper option

- The brand does about 19 percent of their U.S. sales in EPR states with fees

- This new packaging option will require a 16 percent increase in material usage

In this scenario, the savings are significant: $11 million in fees saved across the seven EPR states. Of course, these savings will depend on a multitude of factors, and the cost of switching to a new material needs to be factored in. But even when an alternative such as paper is more expensive, innovation can lead to savings. More back-of-the-envelope calculations show that in this case, a 34 percent increase in material costs would still lead to over $600,000 in net savings. These are just sample calculations, but the take-home message is clear. Strategically switching to lower-fee materials can add up to meaningful savings.

Redeploying savings

Right now, EPR fees are likely going to come out of one part of an organization’s budget and investments in sustainability, new technology, and R&D are coming from another. But what if there could be some feedback mechanisms between the two?

It will take collaboration and shared goals between finance, product and sustainability teams, but once the connection between fees and innovation has been established, you’ll have even more powerful incentives to build sustainability into your budget.

This is when the exciting sustainability work begins. The savings from avoided fees could be used as a way to cover additional R&D and fund more testing into how well packages are being reprocessed at material recovery facilities, paper mills and composting facilities. The savings could also be redirected back into consumer education campaigns, especially around topics such as store drop-off where we know consumers are confused and need more information.

Fees can be a driver of innovation

Right now, the packaging industry has the opportunity to see fees as possible new investment capital. Companies can save money by switching to incentivized, lower-fee materials and packaging formats. Then, they can reinvest these savings back into the sustainable materials that once seemed out of reach.

Your company can get started by:

- Cross reference the materials in your packaging portfolio with the base fees and dues posted for Colorado and Oregon, two states that have posted early fee projections

- Calculate the largest liabilities in your current portfolio, then run back-of-the-envelope calculations on the potential benefits of switching into lower-fee material categories

- Find out how you can make sustainable switches or work with packaging consultancies to support sustainable transformations

Just like the savings from lower energy bills can be directed towards other sustainable home projects, the savings in EPR fees can be funneled towards strategic innovations in materials and recycling infrastructure.

With EPR laws in seven states, the packaging industry has the opportunity to reverse the rebound effect by turning fees into momentum needed to power sustainable packaging’s innovation flywheel.

Subscribe to Trellis Briefing

Featured Reports

The Premier Event for Sustainable Business Leaders