A new approach to a surprisingly carbon-intensive part of offices: interior renovations

Chicago-based architect Perkins&Will has a three-step process for working with clients to make progress on net zero interiors. Read More

- Traditionally, the focus was on reducing operational carbon, e.g., by upgrading HVAC and lighting with more energy-efficient technologies.

- But to achieve net-zero goals, many organizations are shifting their attention to embodied carbon.

- Perkins&Will is a pioneer in this movement.

There’s a gap between organizations’ net-zero promises and the reality of their building stock. With the construction industry responsible for 39 percent of global energy-related carbon emissions, many companies and government agencies have set targets to reduce their buildings’ climate impact.

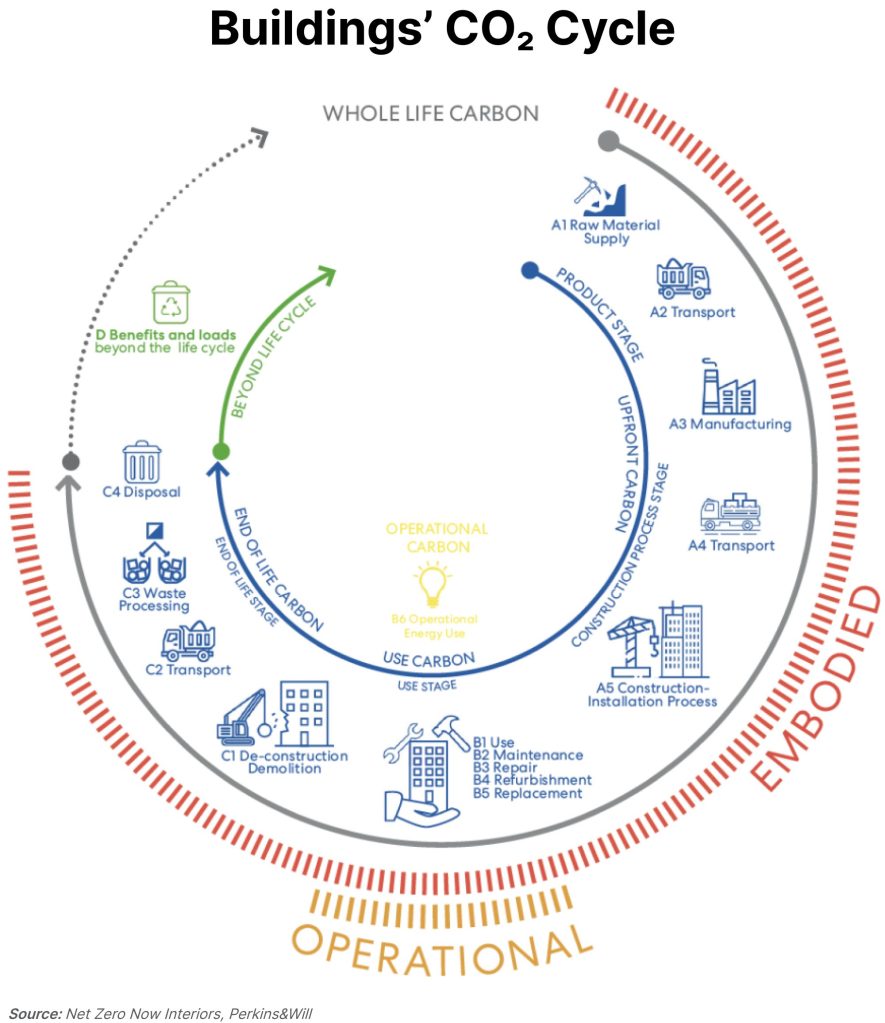

Until recently, the focus was on reducing operational carbon — by upgrading HVAC and lighting with more energy-efficient technologies, for example. But to achieve net-zero goals, many organizations are shifting their attention to embodied carbon — the combined emissions released during raw material extraction, product manufacturing, transportation to construction sites and demolition.

Chicago-based architecture firm Perkins&Will, which has earned seven Top Ten Awards for sustainable design excellence from the American Institute of Architects (AIA) Committee on the Environment, is helping pioneer such efforts. Since signing the AIA 2030 Commitment to achieving net-zero emissions in the built environment in 2011, the firm has increased the energy efficiency of its built projects by 27 percent on average and reduced overall energy use by 58 percent.

Two of Perkins&Will’s studios are focusing on interior renovations, a major but often overlooked contributor to a building’s lifecycle carbon emissions.

Targeting embodied carbon

Even before a building opens, embodied carbon can make up as much as 50 percent of its lifetime emissions.

Then, over its lifespan, renovations every five to 10 years can add as much embodied carbon as the original build. That leaves it to sustainability directors to work with design firms to waste less, reuse more and make considered decisions on products and materials.

“Commercial building renovations that achieve net-zero performance aren’t just good for the planet — they’re smart business,” said Carrie Szarzynski, senior managing director and head of management services at commercial real estate firm Hiffman National. “Lower energy use reduces long-term operating costs, while reusing materials and selecting low-embodied carbon products further cut environmental impact and can lower construction expenses.”

“There are lots of different paths toward net zero and they can survive on their own in parallel or be combined,” said Jon Penndorf, associate principal and studio director for regenerative design at Perkins&Will’s Washington, D.C., studio. “On some projects, adaptive reuse makes a lot more sense than building everything from scratch and looking at the global warming potential of each product.”

Net-zero interiors

Different context, constraints and opportunities mean developing flexible strategies and staying focused on long-term goals — even when the market isn’t fully ready.

In 2020, Perkins&Will’s London studio made the Net Zero Carbon Pledge for Interiors to drive down embodied and operational carbon on projects for clients throughout Europe. The goal was for half of the studio’s projects to be 100 percent circular by the end of 2021 and the rest by the end of 2025 — with all achieving net-zero embodied carbon by 2030. The Washington, D.C., studio followed with its own pledge soon after.

“I think it was a bit of a moonshot,” said Adam Strudwick, Perkins&Will’s principal for workplace. “I don’t think we ever expected that we’d meet all the targets. We wanted to measure ourselves on making the industry change.”

Three steps to success

Perkins&Will’s process for working with clients to make progress on net zero interiors follows three steps:

1. Educate and collaborate

All internal and supply chain teams at Perkins&Will must understand that “fundamentally we need to be designing an architecture that has multiple uses and reduces the need for the extraction of virgin materials,” said Strudwick.

The firm’s goal is to help clients align sustainability with their values, budgets and long-term goals. That includes evaluating whether to move or renovate, how to reuse furniture, where to invest for maximum health for people and the planet, and so on.

In the case of Greenpeace, for example, the nonprofit wanted its new Washington, D.C. headquarters to reflect its mission to reverse negative impacts of climate change. “We had to continue the history of being pioneers and innovators,” said Haiba Bakar, national facilities director for Greenpeace.

Greenpeace collaborated with Perkins&Will to make the headquarters a prototype for climate-responsible interior design. That was helped by choosing the space recently vacated by the American Public Transportation Association (APTA) in the Franklin Square office building in northwest D.C. Reduced use during and after the pandemic left the millwork, ceilings and interior glass of APTA’s conference center in almost perfect condition.

2. View spaces as a material bank

Companies may think only of emptying the space they want to refresh, but Strudwick encourages them to view it as a source of materials waiting for another life.

“Waste is just a material without an identity,” said Strudwick. That calls for reimagining materiality — reusing furniture, reupholstering pieces, refurbishing instead of buying new. “Recycling is not the answer,” he added.

Many components have value in terms of reducing embodied carbon, extending the lifespan of existing materials and cutting costs. For the Greenpeace project, onboarding the general contractor and subcontractors early in the design process enabled the team to maximize material reuse on-site, salvage off-site materials and design for disassembly.

“We used components that you would not expect to be reused,” Penndorf said — including metal studs, gypsum board, ceiling tile and grid, and wood doors, blocking and feature walls.

3. Celebrate achievements

The final step is telling a meaningful story to end users, clients and visitors. That’s a two-pronged tale, emphasizing “the environmental benefit of not throwing everything in the trash as well as the cost benefit of not having to build everything again,” Penndorf said.

Greenpeace achieved a 54-percent reduction in embodied carbon from its baseline lifecycle analysis. The project’s ripple effects continue. Talking to other clients and prospective clients, Bakar said, “What I hear constantly is, we want the same space as Greenpeace.”

Building the market

Two major challenges arise when reducing embodied carbon during renovation. First, when selecting new products, organizations should choose those with low embodied carbon and global warming potential.

Second, when sourcing reused products, be aware that the market is still evolving. “It’s still easier for us to go to Canada, chop down a tree, have it made into a table and bring it to London than it is for us to find materials that are two miles away,” Strudwick said.

He envisions a matchmaking site for requirements and materials — considering factors such as building codes, warranty, cost, transport and, of course, carbon. For now, finding a “donor” building with material that would be valuable in a new project depends on serendipity.

To help design professionals, Perkins&Will has created the free, open-source “Circular Design Primer for Interiors” — which is also intended to help clients buy into the philosophy.

All of this aims at helping to build a design culture that strives to do better, not just to do less harm.

To move from sustainable to regenerative design, “We’re going to have to surpass code minimums and even low levels of current certification programs,” Penndorf said. “We probably need a mindset shift as an industry if we’re going to really drive that forward.”