Moving up the mountain: How Suntory and its suppliers are reducing emissions together

Reducing supply chain emissions is one of the biggest challenges—and greatest opportunities—for global brands. Read More

Building structure and supplier collaboration to reduce Scope 3 emissions

Reducing supply chain emissions is one of the biggest challenges — and greatest opportunities — for global brands. At Suntory Global Spirits, the premium spirits company behind brands Jim Beam, Maker’s Mark and Hibiki, progress on greenhouse gas (GHG) reductions comes from looking beyond internal operations to the suppliers and partners that help make our products. More than 80 percent of emissions are Scope 3, meaning that they come from our value chain, and reducing them takes more than mandates. It requires a clear, strategic structure that invites supplier partnership as the path to meaningful impact. We’re proud of our work to reduce GHG emissions and we’re pragmatic; tackling emissions in isolation is not only less impactful but also more costly in the long run.

We recognize that suppliers face multiple, sometimes conflicting requests, and wanted to avoid adding confusion or burdens as we asked them for Scope 3 reductions. Instead, we set out to develop a strategic, collaborative model focused on emissions hotspots that embedded sustainability into procurement. We identified four key categories to work on — raw ingredients, packaging (with a particular focus on glass), logistics and co-manufacturing — and assigned a steering committee to each that includes leaders from procurement, fulfillment, operations and sustainability.

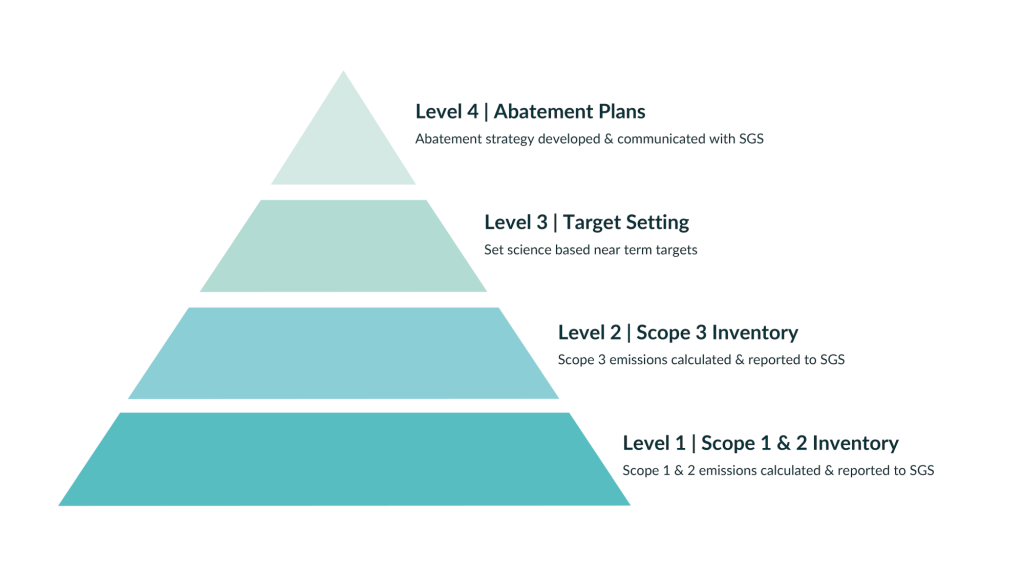

At the heart of our approach is the Supplier Sustainability Maturity Mountain, a framework designed to assess and support suppliers as they progress through four levels of ascending progress towards sustainability. Upward progress towards Level 4 is tracked through detailed scoring rubrics and visual dashboards to maintain transparency between Suntory and suppliers and to celebrate achievements. We built tailored tools and goals for each category. Procurement teams work closely with sustainability leaders to set annual targets, specific to their categories.

Rather than issuing mandates, we engage suppliers directly, asking for feedback and building reduction plans together. Take glass packaging, for example. We work closely with procurement to set category-level goals. Glass category buyers have very different targets from those managing transportation or logistics, and they are empowered to set annual goals aimed at moving their suppliers up the mountain by a certain percentage. We listened to glass suppliers’ input and co-created practical, achievable reduction plans with them, focusing on continuous improvement instead of mandates.

The same structured, collaborative approach guides our work with farmers transitioning to regenerative agriculture. Starting with small pilot projects and scaling up has proven both effective and cost-efficient.

Putting partnerships into practice: Spotlight on Kentucky

One example I am especially proud of is a new five-year, $2.8 million partnership with three competing spirits companies and the Kentucky Distillers’ Association (KDA). We are joining forces with Precision Conservation Management (PCM) to provide tools for corn growers to successfully implement proven practices that will support the long-term resilience of the state’s historic agricultural community while providing economic and sustainable value to regenerative agriculture in Bourbon and distilling.

This initiative underscores what’s possible when industry leaders come together to drive systemic change. KDA members produce the overwhelming majority of the world’s Bourbon, but traditional agricultural practices contribute significantly to Scope 3 emissions. “Farmers are spread thin and are already making hundreds of management decisions each year,” says Greg Goodwin, director of PCM. “They want to do a good job, but face time constraints and decision fatigue when it comes to analyzing data and making changes.” So, buyers teamed up and asked: how can we invest in the same communities that support our business while reducing environmental impact?

The answer is a collaborative partnership of spirits producers and suppliers focused on promoting regenerative agricultural practices such as cover cropping, reduced tillage and optimized fertilizer use. The group engages conservation specialists to help farmers implement regenerative practices on more than 100,000 acres over five years, starting in 2025. The program also benchmarks farm finances against anonymized statewide data, helping farmers make informed, profitable decisions regarding conservation practices.

Scaling innovation in key raw materials globally

Beyond Kentucky, Suntory is piloting regenerative agriculture across key sourcing regions for other crops, including barley in the United Kingdom and agave in Mexico. These pilots reflect the same structured and collaborative approach outlined in our maturity mountain framework: working closely with suppliers to co-create solutions that drive both environmental and economic benefit. Our Casa Sauza tequila brand is testing carbon capture technology in production, while Maker’s Mark, a certified B Corporation, has achieved Regenified Tier 2 certification and is on track to source 100 percent of its corn from Regenified farms by 2025. These pilots demonstrate how structured collaboration can scale innovation and deliver tangible progress toward climate goals. They are strong examples of how Suntory lives its core values of Growing for Good and Giving Back to Society.

Conclusion: The power of structured collaboration

Achieving net-zero goals and reducing Scope 3 emissions requires more than intention, it requires structure, trust and collaboration. At Suntory, we have made real progress on our Scope 3 reductions by combining clear frameworks, shared goals and meaningful supplier engagement. The results of efforts in Kentucky, along with global pilots in key sourcing regions, show what’s possible when companies work alongside suppliers rather than prescribing solutions. This approach not only advances sustainability but also strengthens supply chains and creates lasting value for communities. For those beginning their Scope 3 journeys, starting small, focusing on emissions hotspots and building from there can lead to scalable, industry-wide impact.

Subscribe to Trellis Briefing

Featured Reports

The Premier Event for Sustainable Business Leaders