Why MilliporeSigma’s sustainability lead sits in on sales pitches

Jeffrey Whitford, the company’s vice president of sustainability and social business innovation, uses customer feedback to prioritize projects and guide product development. Read More

- Packaging accounts for 10 percent of parent Merck KGaA’s overall emissions.

- The company has already surpassed its Scope 1 emissions target.

- The annual R&D budget includes a dedicated fund for sustainability projects.

MilliporeSigma’s 40-person sustainability team reports to the chief strategy and transformation officer of parent company, Merck KGaA, Darmstadt, Germany.

That means environmental considerations are automatically included in product design and packaging decisions, and the lead sustainability executive for the life sciences company often accompanies sales representatives to meetings with strategic accounts.

“I see firsthand where it’s creating a more attractive environment for our customers to choose us more often because of what we’re doing related to sustainability,” said Jeffrey Whitford, vice president of sustainability and social business innovation at MilliporeSigma, the operating name for Merck KGaA’s U.S. and Canadian life science business. “We’re changing the narrative that it’s costs, costs, costs. We’re finding the connection points to make the financial picture much clearer and, I would say, much more attractive for the business.”

Clear results

Even when Whitford isn’t in the room, MilliporeSigma’s climate agenda is a component of how the company pitches new accounts and wins new business. It considers both potential savings and sales upsides during the product design process, something it has been doing since 2021 when sustainability started reporting to the strategy team. (Whitford started in environmental, health and safety 20 years ago with Sigma-Aldrich, which was acquired by Merck KGaA in 2015.)

That reorganization has served the company well.

Merck KGaA’s company-wide commitment, validated by the Science Based Targets initiative, calls for a 50 percent reduction in greenhouse gas emissions related to its operations and purchased electricity by 2030 (Scope 1 and 2, respectively) compared with 2020. It has cut Scope 1 by 53 percent and reduced Scope 2 by 30 percent. Merck KGaA has an emissions intensity goal that calls for it to cut emissions to 230 metric tons of carbon dioxide equivalent per 1 million euros of gross profit; the result for 2024 was 359 metric tons of CO2e.

Sales for MilliporeSigma’s Greener Alternatives Portfolio — more than 2,500 products that contain bio-based solvents or chemicals, were repackaged with fewer plastics and more renewable materials or have some other preferable sustainability attribute — doubled in the past year.

MilliporeSigma sells more than 300,000 products. The company doesn’t disclose what percentage of its annual sales for 2024 were attributable to Greener Alternatives. It added more than 880 products to the portfolio in 2024 including mPredict, an artificial intelligence tool that uses green chemistry concepts to help scientists eliminate thousands of physical screening experiments, and Cellvento, a feed solution that doesn’t need to be refrigerated, saving energy.

Dedicated packaging plan

One place where sustainability goals win over MilliporeSigma customers is packaging, which contributes 10 percent of the company’s emissions. Merck KGaA has committed to reducing packaging weight per unit sales by 10 percent by 2030, ensuring that all fiber materials are deforestation-free, and designing packages to be recovered, recycled or reused.

The more than 100 projects the company has completed under its SMASH Packaging 2.0 initiative have cut emissions by more than 400 metric tons on an annual basis. Many products are distributed in glass, because it doesn’t react with certain chemicals, but the company is taking steps to reduce plastic-derived and fiber-based materials where possible.

One example is the bulk packaging option MilliporeSigma adopted for several filter product lines, including Millstak (which removes particulates and clarified liquids during biopharmaceutical manufacturing) and Clarisolve (used with cell cultures). The approach reduces waste by 33-53 percent and also cuts the time it takes customers to unbox them in half.

“So, they have a reduction in the CO2 footprint, they have a reduction in operator time, and they have a reduction in the amount of waste they have to deal with,” Whitford said.

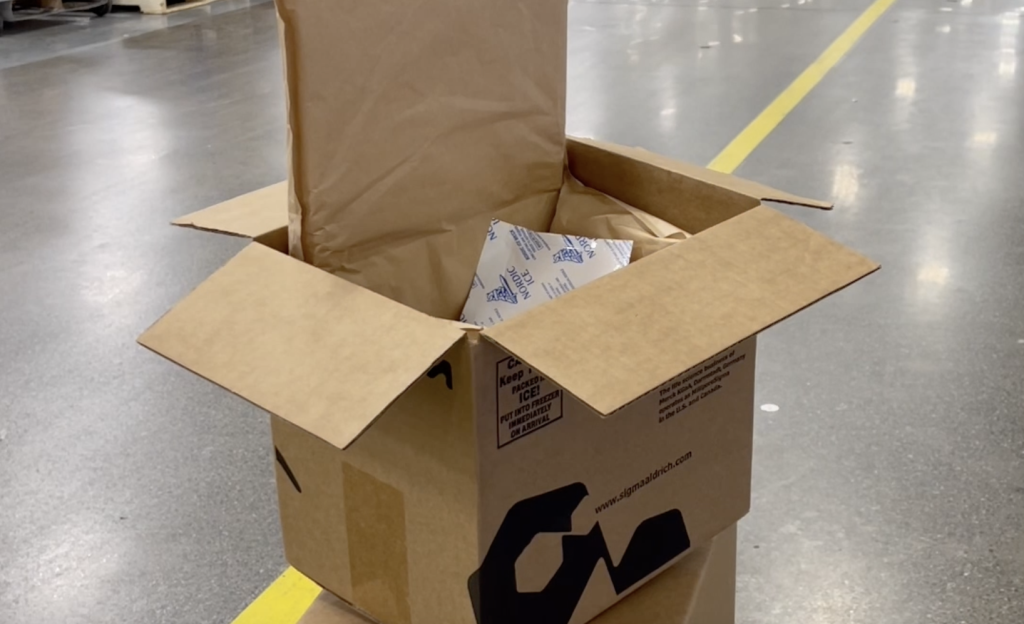

MilliporeSigma also stands out for its Green Cooler initiative, replacing the styrofoam typically used to transport refrigerated items such as blood products or antibodies with an insulated starch and paper-based option that can accommodate dry ice and disposed of in curbside recycling systems. Recycling instructions are printed directly on the cooler’s inside flap.

MilliporeSigma handled 60,000 shipments using the Green Coolers in 2025 in Australia, Germany, Korea and the U.S. The new coolers will be introduced to all U.S. distribution centers in 2026, eliminating an estimated 60 metric tons of styrofoam annually — six jumbo jets’ worth of material.

Two challenges in rolling out the new format was satisfying quality control teams and training distribution employees how to handle the coolers. For example, a distribution center in Phoenix, where summer temperatures can soar above 100 degrees Fahrenheit, must have confidence that a shipment arriving late on a Friday will stay cold over the weekend.

“These are the things you uncover when you’re encouraging change, and you have to figure out how you have the resilience to navigate them and not get thrown off by the hurdles,” Whitford said.

Hybrid funding approach

Because sustainability considerations are part of MilliporeSigma’s commercial plan, the investments for supporting programs such as the Green Cooler initiative come from two main sources: product development budgets and strategic development funds that are meant for longer-range projects.

The chief technology officer has also dedicated a portion of the corporate research and development budget to sustainability-related innovation, further demonstrating the company’s high-level commitment.

“The biggest constraint is time, to be honest, because we are really fortunate to be in an organization where I have been given freedom to go and run,” Whitford said.