How Bugaboo is pushing low-emissions strollers forward

The Amsterdam company is betting on modular design, repair and recycled materials in an industry largely stuck in linear mode. Read More

- Most strollers end up in landfills.

- Bugaboo is scaling circular models, but refurbished and leased sales still make up only 1.4 percent of revenue.

- Materials drive 91 percent of the company’s emissions, making deeper innovation essential to reaching its 2026 goal.

The lifespan of a stroller is as fleeting as a childhood. Even if used by more than one family, strollers ultimately land in a dump. Recycling infrastructure doesn’t exist.

Bugaboo is an outlier in the industry for emphasizing durability, sustainable materials and circular business models. Such efforts support its net zero goal for 2035, which requires addressing the 91 percent of emissions that stem from materials.

“I’m still surprised about this, but sustainability is not top of mind for consumers when they’re buying a pram or stroller,” said Melanie Wijnands, head of ESG at Bugaboo, based in Amsterdam. “It’s not a message that we, as an industry, are pushing. I hope by talking about it more as a brand, we’re putting it a little bit more top of mind with consumers.”

Only 30 percent of stroller sales were “eco-friendly” models last year, according to one count.

Slimming the product footprint

Much work remains for the industry to zap waste and shrink its climate footprint. About 19 million strollers were sold globally from 2020 to 2023, according to 360 Research Reports, in a $10.5 billion market set to reach $16.6 billion in 2034. That’s a lot of virgin plastic, aluminum and polyester for landfills.

A handful of companies have 40 percent of stroller market share, including Good Baby International Holdings, Chicco and Graco. With 943 employees, Bugaboo is among the smaller, premium players.

Circular models and durability

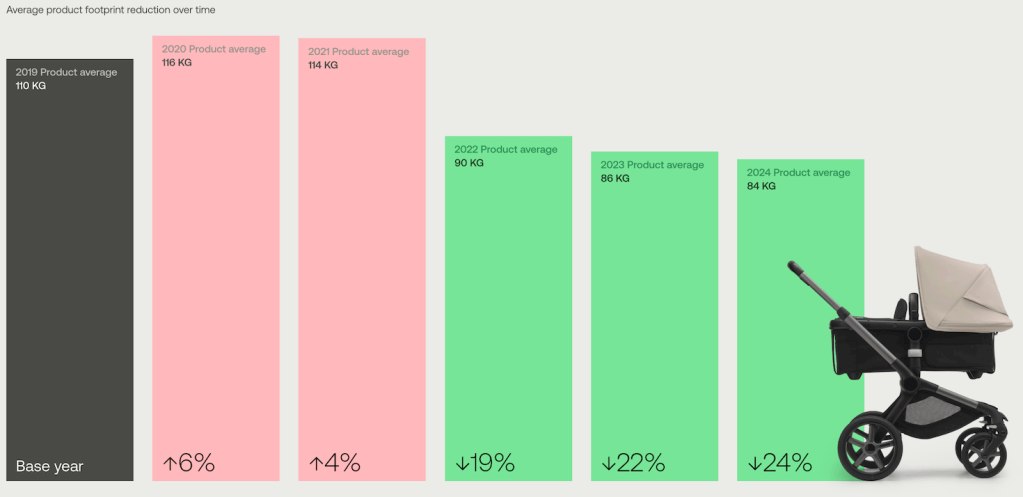

Bugaboo has measured early success in circularity. Its revenues from refurbished and leased products doubled from 2019 to 2024, while the average carbon dioxide footprint of its goods fell by 24 percent. Even as the certified B Corporation made 93 percent more products, its emissions rose by a comparatively low 38 percent.

Even as Bugaboo’s circular sales doubled, they only made up 1.4 percent of revenues in 2024.

Still, that’s something in a space that has left repair and recycling to informal networks of families, friends and charities. Parents also turn to independent stores or Facebook Marketplace. eBay lists 3,100 strollers at the moment. Newer secondhand marketplaces such as Rebel and GoodBuy Gear are growing.

Through a third party, Bugaboo refurbishes, cleans and re-lists 98 percent of products returned under warranty by European customers. Partners Tiny Library in the Netherlands, StrollMe in Germany and Parently in Sweden manage stroller leases.

Bugaboo plans for its products to last the equivalent of 3.5 trips around the planet. That’s between four to 13 years of life for its $1,200 Fox 5 stroller.

Durable, modular and glue-free goods remain Bugaboo’s design focus for circularity. A bassinet basin doubles as a car seat. The $1,449 Kangaroo stroller can expand to fit a sibling. Parts such as brakes are available for older, popular models needing repair.

Bugaboo recently found that 25-year-old models were still being resold. “Our head of design, who’s been with us for 25 years, was geeking out,” Wijnands said.

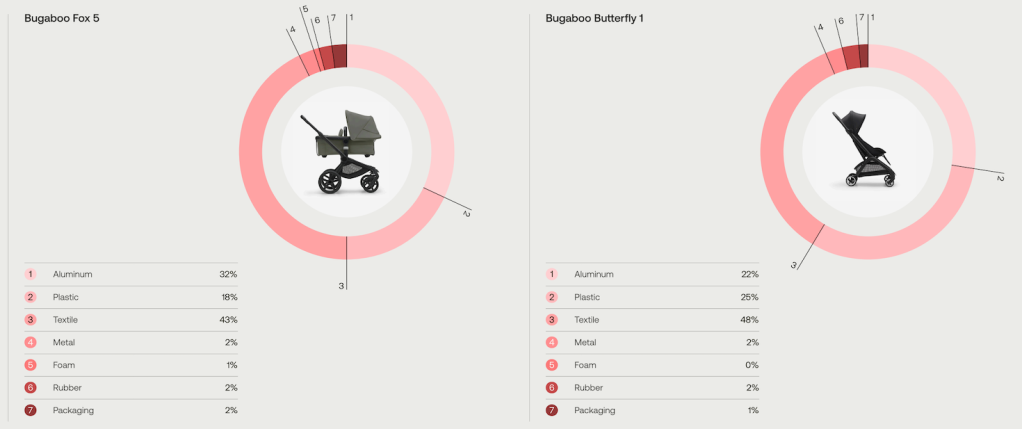

‘Carbon anatomy’ of two strollers

Materials

Adopting alternatives to carbon-intensive textiles, aluminum and plastics is core to Bugaboo’s near-term target, aproved by the Science-Based Targets initiative. The company plans to slash the average CO2 equivalent footprint of its products by 47 percent by 2026. (It has already met its Scope 1 and 2 goals.)

“To be completely honest, we’re not entirely sure how we can get there,” Wijnands said, noting that biobased plastic and recycled industrial aluminum have already helped. After introducing fabrics recycled from polyethylene terephthalate (PET) bottles last year, the company is looking into textile-to-textile recycled polyester.

Among other material concerns, chemicals safety resonates with Bugaboo customers. “Children sometimes lick the side of their stroller or get anything and everything into their mouth,” Wijnands said.

Bugaboo doesn’t use forever chemicals such as per- and polyfluoroalkyl substances (PFAS) or anti-bacterial coatings, a newer target of watchdog groups. Some of its textiles are OEKO-TEX certified.

Supply chain

Bugaboo has a unique level of control in owning its production facility in Xiamen, China, which is 25 percent powered by renewables. “We work really closely with our first-tier suppliers,” 80 percent of which are gradually getting rid of fossil fuels, she added.

Wijnands joined Bugaboo from consultancy Circle Economy, which publishes a semi-annual global circularity score. The only full-time sustainability staffer, she reports to CEO Adriaan Thierry. Wijnands works closely with Bugaboo’s lead engineer on carbon accounting, head of design and the product team.

“We’ve been really focusing on getting the carbon of our products down, but more and more, we’re also realizing that circularity is a promising route,” Wijnands said.