Decarbonizing operations in the beverage industry

Learnings from Diageo’s journey decarbonizing its operations, making them more resilient and sustainable. Read More

This article is sponsored by Diageo North America.

Diageo’s ambition as a premium drinks company —that relies on raw materials, water and heat— is to build a more resilient and sustainable supply chain. This is reflected in the company’s grain-to-glass sustainability strategy and supported by an expected $1.2 billion investment to drive projects in this space across the globe by 2030.

The company’s priorities include reaching net zero carbon in direct operations across the world by embedding energy efficiency and using only 100 percent renewable energy, fuel and heat by 2030.

Invest to reduce carbon emissions across production facilities

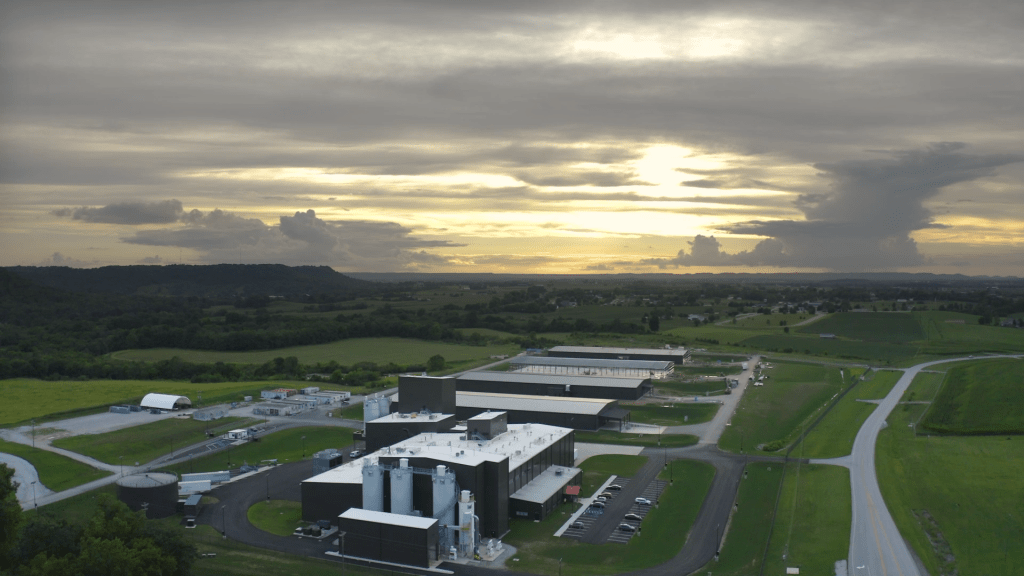

Diageo produces its iconic portfolio across a large global production footprint. Each site offers a chance to pioneer carbon technology and practices and model best-in-class approaches to full facility decarbonization. In addition to its four carbon neutral distilleries in Scotland and the United States, the company is designing new sites in Mexico and China to be as efficient and low-emitting as possible. Diageo recently announced investment plans to decarbonize by 2030 the historic St. James’s Gate site in Dublin, where Guinness has been brewed for 264 years. In North America, these efforts are reflected in Diageo’s Lebanon, KY, distillery —which mainly produces Bulleit Bourbon— and the Valleyfield, Quebec, site where it makes Crown Royal.

Make a business case

The corporate incentive to invest in sustainability has never been stronger. Beyond the positive impact on the environment, Diageo looks at every project through the lens of a triple-win framework, understanding how it benefits communities where the company operates, its customers and consumers, and the bottom line of its business.

A great example of this approach is Diageo’s investment in biomass and solar energy initiatives in Africa. By installing biomass boilers and solar panels across three of its brewing facilities, the company is producing large amounts of energy as it uses renewable sources to produce the power, significantly reducing greenhouse gas emissions. The boilers are fueled with local agricultural waste —including rice and coffee husk, woodchip, macadamia and bagasse— building community resilience by reducing waste, creating jobs and supporting more farmers within its supply chain. The cost-effective nature of the biomass materials has resulted in huge productivity savings.

Design energy sourcing for long-term performance

To ensure long-term performance when evaluating solutions to decarbonize operations, every project should be designed to be fit for purpose according to the site and location. Considerations include: the availability and adaptability of the space for new equipment; requirements for ingredient delivery, storage and processing for its products at the site; and the available sources of energy to power the site.

Looking closer at energy sourcing, Diageo considers the utility and grid structure in each community, asking, “Are there affordable, renewable sources of power already online, or do alternatives need to be considered to reach net zero?”

In Canada, Diageo partnered with the local producer Hydro-Québec and designed a project to build the required infrastructure: a new powerline from the closest electrical substation to the Valleyfield facility, which will be powered by a mix of renewable energy sources that includes hydroelectricity. In Lebanon, KY, the company secured a long-term agreement with local utilities —Eastern Kentucky Power Cooperative (EKPC) and Inter County Energy (ICE)— and partnered to build a substation and delivery infrastructure to supply its bourbon distillery with renewable electricity.

Understanding a region’s electric grid mix, existing infrastructure, utility structure and capabilities for sourcing renewable energy will help your organization custom fit its sustainable facility innovations. Engaging local utility contacts and community members can help with this understanding.

Use your footprint as an innovation testing platform

Because premium product consistency is so important to Diageo, it needs to maintain the integrity of the processes that go into crafting its beverages —milling grain, cooking, fermentation, distillation and maturing— while still reducing GHG emissions. The company is incorporating innovative technologies across its production footprint to test different approaches to decarbonization and identify which ones can scale the most cost-effectively.

Under this principle, Diageo installed 22-foot-tall, high-voltage jet electrode boilers at the Lebanon, KY, distillery to generate intense heat via steam modulation (instead of traditional natural gas-fired equipment), all powered by a mix of 100 percent renewable wind and solar sources. This technology allowed Diageo to avoid approximately 117,000 metric tons of emissions annually and brought other benefits to the operations, including reducing noise pollution, air pollution and maintenance needs.

Diageo also looked at new solutions for current production sites in Shelbyville, Kentucky, and Plainfield, Illinois. The company will partner with Rondo Energy to install its pioneering Rondo Heat Batteries at these facilities, providing low-cost, zero-carbon heat and power, and eliminating reliance on natural gas for boilers used in heating processes. This technology will allow each facility to capture and store renewable energy, delivering continuous industrial heat and power. With this new technology, the Shelbyville and Plainfield locations are expected to be carbon neutral by 2026 and 2028, respectively, and eliminating nearly 17,000 metric tons of emissions.

With the benefit of sites in different geographies and different configurations, Diageo can test and learn, identify risks and identify ways to scale the most promising and cost-effective solutions.

I am proud of the positive impact generated through the ongoing decarbonization of Diageo’s North American facilities —and global efforts— and look forward to further ushering in a more sustainable beverage industry.