Google parent Alphabet’s skunkworks targets the plastic crisis

The "X Moonshot for Circularity" initiative seeks to yield value from more than plastic. Read More

Eighty percent of plastic, made from fossil fuels, gets thrown out rather than recycled. Recycling plants lack the tools to identify and sort the myriad types of plastics. Even when plastic products are recycled, the lower-quality product that results eventually rots in a landfill.

Alphabet’s secretive skunkworks is throwing its data-center weight and computing wiles behind these problems. Its X Moonshot for Circularity, launched Nov. 15, aims to to hasten a circular economy for plastics. But it’s not stopping there. The team believes its work can apply to other hard-to-decarbonize materials, such as steel, concrete, batteries, electronics and textiles.

The vision is to “to realize a world without waste, building what we call a molecular inventory management platform,” said X Director and and Project Lead Rey Banatao, in a company video announcing the “moonshot.”

Formerly called Google X, the research and development arm of Alphabet, of Mountain View, California, is using its computing might, data skills and artificial intelligence to solve one of the world’s hardest materials challenges. X, the Moonshot Factory, has built a system to identify types of plastic by their molecules in real time, capable of speeding through thousands of pieces a minute on recycling plant conveyor belts.

X is also creating a database to store what it learns and assist recyclers with future plastic identification. It’s exploring both mechanical and chemical recycling.

Meanwhile, plastic production has doubled in the past two decades, and only 9 percent of plastic gets recycled, according to the 2022 Global Plastics Outlook by the Organisation for Economic Co-operation and Development (OECD). Only 21 percent of recyclable items make it into the recycling system, according to The Recycling Partnership.

‘Absolutely can be fixed’

“It absolutely can be fixed,” said X CEO Eric “Astro” Teller, on Google’s “Where the Internet Lives” podcast, which aired Nov 6. “And this is another one of these system problems. You have the people who make the plastic, the people who make the raw materials for the plastic, the people, like individual citizens, like ourselves, who may or may not have lost our faith in those blue bins in the first place, the recycling centers and what their current habits are. This whole system has to be rewired. Can it be done? One hundred percent. We’re not done, but we are far along.”

The X team has worked for at least several years on the secretive projects. They even measured their own household waste with infrared scanners. In 2021, Google partnered with Recology, based in Brisbane, California. The waste management company sent food containers, Tupperware and other hard-to-recycle materials to the X group for testing.

It wasn’t possible even a few years ago to process data at a high speed from hyperspectral imaging, which collects data from across the electromagnetic spectrum, according to Banatao. Such images of materials can reach into the thousands of megabytes. “And now imagine analyzing thousands of objects like in a minute,” he said. “That’s a lot of data that you need to be able to store and process and apply machine learning to.”

It generally takes two decades for technologies to travel from a lab to industrial scale. Some of the technologies X is working on are maybe at the five to 10 year mark, while enzymatic recycling just began its journey, according to Banatao.

“We don’t have 20 years to wait around,” Banatao said on Google’s podcast. “So for us, the big breakthrough is, how can we accelerate that time scale, using technologies like machine learning and the data that we’re collecting at this more granular molecular level, and everyone’s trying to run really fast towards these large target.”

Banatao, who has invented recyclable and biobased sporting goods products, including surfboards, was attracted to Google X for the potential to apply its unmatched computing power to materials sustainability problems.

Moonshots since 2010

Since 2010, the X “moonshot factory” has been tackling pie-in-the-sky solutions to mega challenges. How many work there and on how many projects is under wraps, but X shared that half of its projects now relate to climate change. Among those technologies are 280 Earth direct air carbon capture, Tidal underwater cameras and Bellwether wildfire detection. Self-driving cars, which led to Waymo, are another of many. Alphabet is increasingly spinning off X’s creations into businesses to amplify their impact, according to the lab.

“When it comes to plastic, we desperately need innovation to jump start the circular economy,”said Joy Rifkin, head of sustainability at Lakeshore Recycling Systems in Chicago. The waste management company adopted AI-enabled sorting systems from EverestLabs about a year ago. “I am intrigued by the appearance of AI in the waste and recycling space.”

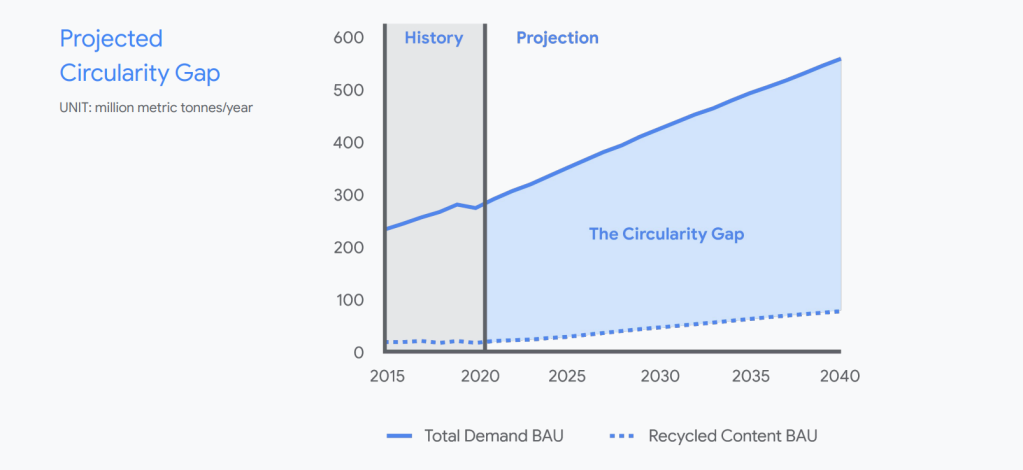

Google in 2019 launched a circularity initiative to focus on designing out waste from products, extending the life of products. In July 2021, its report on “Closing the Plastics Circularity Gap” foreshadowed the work of the new X Moonshot.

“Since the report, our industry partners have reaffirmed just how complex this is,” Banatao told Trellis. “Tech plays a critical role in informing and connecting all the different players in the value chain. The industry needs better data and platforms to manage that data. That’s what we’re aiming to do.”

AI startup EverestLabs, based in Fremont, California, seeks to automate the sorting process at recycling plants and help recyclers recover more materials. Google can be influential through its relationship “in the front end of the recycling process where packaging is generated more than the back end where packaging is recovered,” said Apurba Pradhan, EverestLabs’ head of product and marketing. For example, what if Google could help to catalog and control the millions of units of consumer packaging coming to the market? This would bring “a sort of consistency in how brands introduce new packaging that aligns with the recycling processes,” he said.

Not everyone, however, is sold on Alphabet’s vision. “The conversation about circularity is just a continuation of other voluntary actions that enable the continued use of fossil fuels—in this case, in plastic,” said Auden Schendler, author of the forthcoming book “Terrible Beauty: Reckoning with Climate Complicity and Rediscovering our Soul.”

“Think about the beverage companies that claim to love recycling but hate (and oppose) bottle bills,” he said, likening that to Alphabet’s support for the U.S. Chamber of Commerce, which often opposes climate action.

[Connect with an unparalleled community of peers with proven track records of impact at speed and scale at GreenBiz 25, February 10-12, Phoenix.]