Scaling the value hill: How to incorporate circular economy practices into the building sector

The business opportunity to convert building sector waste into valuable resources promises hundreds of billions of net profit gains. Read More

The French firm Saint-Gobain has become a leader in applying circular economy practices in the building sector. Source: Jean Lucichard via Shutterstock

More than 90 percent of all materials extracted and used in industrial processes are wasted, according to the World Green Building Council. The business opportunity to convert that waste into valuable resources is huge. Applying the circular economy to the building sector, for example, has “the potential to yield an annual net profit gain of $31-46 billion by 2030 and $234-360 billion by 2050,” according to a 2023 report from McKinsey.

The World Green Building Council defines a building as circular if it “optimizes the use of resources whilst minimizing waste throughout its whole lifecycle.” Within the context of the built environment, that can happen at multiple scales, from the products that make up buildings to the cities they operate in. In addition to reducing waste, creating a circular building sector can also help decarbonize building products and improve the resilience and adaptability of our buildings.

Building product decarbonization

Applying circularity “could abate 75% of embodied emissions from the built environment,” according to a report by McKinsey for the World Economic Forum. Embodied carbon encompasses emissions from the extraction, production, transport and manufacturing stages of a product’s life. Although it makes up 11 percent of emissions from the building sector, it has historically been overlooked. That focus is changing as building professionals, led by non-profits such as Mindful Materials and the Carbon Leadership Forum, work to provide data about the lifecycle impacts of building products and materials.

The circular approach to decarbonizing products includes replacing the extraction of raw materials from nature with urban mining, the process of capturing valuable materials from the built environment’s waste stream. Reusing these otherwise wasted materials and products in the manufacturing process helps offset or avoid carbon that would otherwise be emitted.

Circular value creation

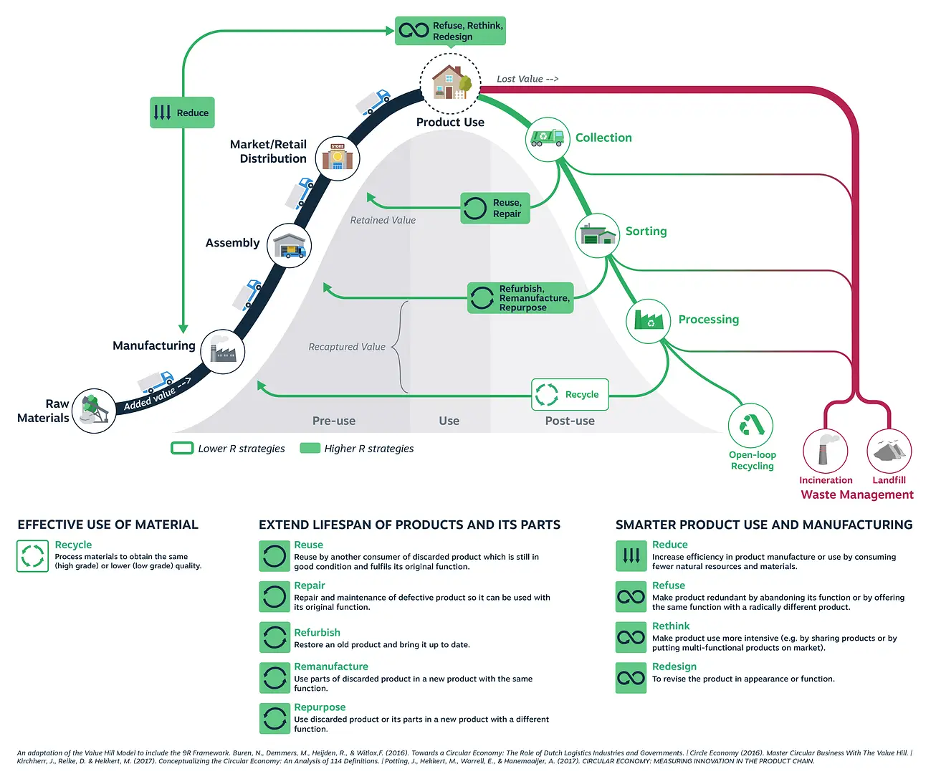

The “value hill” represents a model for how to think about circular opportunities in the building lifecycle. As materials move through the stages of manufacturing they increase in value, reaching their highest value at the top of the hill. In a linear economy that value drops off to nothing on the other side of the hill, while circularity enables multiple opportunities to recapture some of that value.

Source: Metabolic

Incorporating circular practices

French firm Saint-Gobain has manufactured building products for 350 years, starting as the Manufactory of Mirror Glass in 1665. It now has 160,000 employees across 76 countries and is committed to achieving net zero carbon emissions by 2050.

Saint-Gobain is working across the lifecycle of its products to incorporate circular practices, said Dennis Wilson, vice president of ESG and managing director of circular economy solutions for North America. “Upstream, we are actively working with our suppliers to, first report specific data on what become our scope 3 emissions, and then to work with those suppliers to reduce the emissions associated with those materials,” said Wilson.

Saint-Gobain is committed to completing life cycle assessments (LCAs) for all their products by 2030. LCAs quantify the impacts across a product’s lifespan and are critical for architects and engineers to make informed decisions when selecting materials and products. Saint-Gobain is also developing ways to repurpose materials that would otherwise end up in landfills. One example is a partnership to reuse pre- and post-consumer windshield glass in manufacturing insulation. “This model helps us to reduce Scope 3 emissions, but also Scope 1 and 2 emissions since it takes less energy to remelt recycled glass than it does to make glass using virgin raw materials,” said Wilson.

The Building Product Forum

North America is behind Europe in adopting circular economy best practices. In order to capture the value of this approach the building industry needs to get in the same room to work through how to accelerate circular solutions, GreenBiz will host such an event at Circularity 2024, May 22-24 in Chicago.

The Building Product Forum will convene leading building product manufacturers to collaborate on the future of circular building materials. Leading organizations facilitating the transition to a more sustainable future for buildings lead the discussions, providing a unique opportunity to convene with product manufacturers from across the building sector in a collaborative format to align efforts on their shared ambitions for a more sustainable and circular built world.